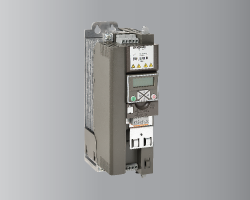

Introducing speed control to Oil and Gas operations can result in considerable energy savings and improved process control. Variable Frequency Drives from H2flow were developed specifically for applications such as pumps, compressors, and mixers - just like those found in Oil and Gas facilities! Refineries everywhere use AC Drives from H2flow to improve process reliability, reduce energy consumption, and decrease wear on equipment.

Soft Starters offer several of the same advantages as AC Drives for these applications, perhaps most notably in pump applications, where they enable the customer to eliminate the harmful effects of water hammer.

Monitoring solutions from H2flow are frequently used at Oil and Gas facilities on pumps to protect them from the damage caused by dry running, dead heading, and cavitation. These monitoring solutions reduce downtime and equipment wear, and increase product reliability and productivity.

OPTIMUM PROCESS CONTROL FOR THE OIL & GAS INDUSTRY.

IMPROVED PROCESS CONTROL. REDUCED COSTS.

AC Drive and Soft Starter solutions from H2flow improve process reliability and efficiency while also reducing energy costs and wear on process equipment.

CONTROL

PROTECTION AGAINST ABNORMAL CONDITIONS.

Protect your pumps against abnormal conditions such as dry run, dead head and cavitation conditions with monitoring solutions from H2flow Controls.